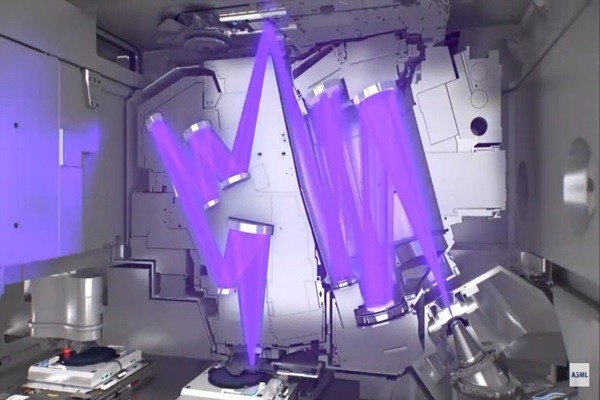

Investments on key materials that are used for the EUV (Extreme Ultraviolet) lithography process are set to be in full swing. Although relevant technologies have been drawing attention as major South Korean semiconductor companies recently started to introduce the EUV process to their production lines, there have been criticisms towards weak foundations of relevant materials, components, and equipment that will support such investments. It is expected that these investments will expand the base of South Korea’s R&D ecosystem for the EUV process.

According to the industry on May 26, the Ministry of Science and ICT (MSIT) will invest $9.5 million (11.7 billion KRW) for the next 5 years in “EUV absorption and penetration materials technology for the semiconductor lithography process under 5nm” project as part of the “Materials Innovation Project”. Including investments from the private sector, total of $11 million (13.6 billion KRW) will be invested.

The key to the project is to localize materials that are a must for the EUV lithography process that is seen as a cutting-edge semiconductor manufacturing technology. Korea Electronics’ Technology Institute (Convergence Electronics Materials Research Center, Kim Hyung-geun (person in charge)) will oversee the project. Also, “EUV-IUCC”, which is a research consultative group for the EUV lithography technology that was established last year by Professor Ahn Jin-ho of Hanyang University, will be in charge of concentrating abilities from domestic and foreign companies, the academic world, and research institutions.

Participating institutions and organizations will develop technologies that can mass-produce products that have emerged as “blue oceans” within the EUV ecosystem that is in its blooming phase. Specifically, they will work on EUV mask blank and EUV pellicle.

Mask blank indicates a mask that is used for the lithography process before it is covered with the pattern of a circuit. Unlike the ArF lithography process that is based on penetration, EUV masks require a high level of technologies as they need to “reflect” EUV light sources that are easily absorbed by every matter. Although the market is led by Japanese companies, it is seen as a promising market as Applied Materials, which is the top semiconductor equipment manufacturer in the world, has started developing relevant technologies.

EUV pellicle indicates a cover that protects a mask from getting contaminated. Pellicle reduces defectives percentage and number of times photomasks are replaced. However, it is likely that it will take some time before EUV pellicle is commercialized.

FST and SNSTech are South Korean companies that have started working on development of these materials.

FST will focus on EUV pellicle as it has specialized in pellicle for the ArF lithography process. It will be interesting to see whether the company can enter next-generation fundamental technology markets by securing a technology to manufacture EUV pellicles.

Although SNSTech is heard as a company that develops EUV pellicle, it will attempt to develop EUV mask blank and secure a wide range of products as quickly as possible.

In addition, reliable allies that can immediately evaluate the performance of EUV pellicle and EUV mask blank when they are developed have been secured. Pohang Accelerator Laboratory, which is under POSTECH, will develop a technology that can inspect properties of materials using an EUV beam while Korea Research Institute of Standards and Science will prepare technology standards and evaluate thermal and mechanical characteristics.

Major corporations are also expected to participate as it is expected that there will be a high possibility that Samsung Electronics and SK Hynix will apply domestic technologies to their next-generation lines.

Korea Electronics’ Technology Institute is planning to secure at least ten A-level patents through the project. This project is meaningful from a standpoint that it will become an opportunity for South Korea’s EUV ecosystem that had been relatively slow to expand rapidly. Also, it will be interesting to see whether south Korean companies can secure new technologies and establish their influence within the global EUV market that has been led by Japanese companies such as Hoya, Mitsui Chemicals, and Asahi Glass.

“We expect this project to expand towards other key materials such as EUV photoresist and others that have become issues since the Japanese Government imposed trade restrictions last year.” said a representative for the industry.

Staff Reporter Kang, Hyeryung | kang@etnews.com