Performance enhance material for EV battery cathode materials

Expansion capacity of 3,200 tons per year by 2024

Annual capacity of 6,100 tons when Daesan plant 4 is completed

“Spurs the development o

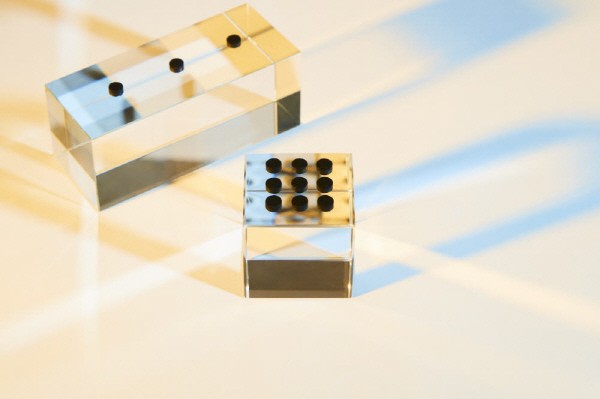

LG Chem will secure the world's largest production capacity of carbon nanotubes for cathode materials. Multi-walled carbon nanotube (MWCNT) is core material to enhance the energy performance of cathode material, which is core material for EV batteries. LG Chem will expand their MWCNT production capacity to 6,100 tons by 2024 and target the global EV battery market.

LG Chem announced on the 30th that they are building the 4th CNT plant at the Daesan plant in Seosan, Chungcheongnam-do. A production capacity of Factory 4 is 3,200 tons which is the largest production capacity of a single plant in Korea. It is the expansion of the 4th factory followed by the commercial operation and the start of construction of Yeosu 2nd and 3rd factories. The three factories in Yeosu have an annual production capacity of 2,900 tons. LG Chem will secure a total of 6,100 tons of MWCNT production including the construction of the 4th plant.

CNT is a core material that supplement the performance of EV battery materials. They are used to enhance the performance of cathode and anode materials. As a global EV battery material company, LG Chem is strengthening their cathode auxiliary material portfolio, including cathode materials and MWCNT.

Most of LG Chem's MWCNT is supplied to LG Energy Solution, which is their subsidiary and a global battery company. LG Chem first operated the CNT 1 plant with 500-ton capacity in 2017 and is expanded their CNT plant every year in accordance with the market expansion in 2020.

LG Chem's CNT plant uses cobalt catalysts to reduce the content of foreign magnetic substances that can affect battery quality to achieve world-class quality. In particular, CNT Plant 4 improved efficiency of the production line operation scale, which improved 20% of productivity per person compared to the previous one.

The CNT market for EV battery is expected to grow to 3 trillion KRW (2.3 billion USD) by 2030. Demand of CNT is expected to grow by more than 30% annually from 5,000 tons last year to 70,000 tons in 2030.

LG Chem is not only expanding the application of CNTs to EV battery materials, but also trays for semiconductor processing, and planar heating elements for road freezing (Black Ice) prevention.

Kug-lae Noh, head of the Petrochemical Business Division of LG Chem, said “We will build a number 1 position in the battery conductive material field with manufacturing competitiveness and excellent quality based on proprietary technology and pioneer into the large new market with much potential.”

By Staff Reporter Ji-woong Kim (jw0316@etnews.com)