Demand surge of 130~180 nano BCD process

Utilization of automotive and display semiconductor manufacturing

Win-win cooperation with customers... product development at ease

DB HiTek will increase the 'Multi Project Wafer (MPW)' service, which supports the production of semiconductor fabless prototypes, by 20% from the original plan. Following last year, the company plans to help develop semiconductor products that are rapidly increasing this year from receive additional demand. It is noteworthy that the decision was made while foundry companies reduced or adjusted MPW quota one after another due to a shortage of semiconductor supply.

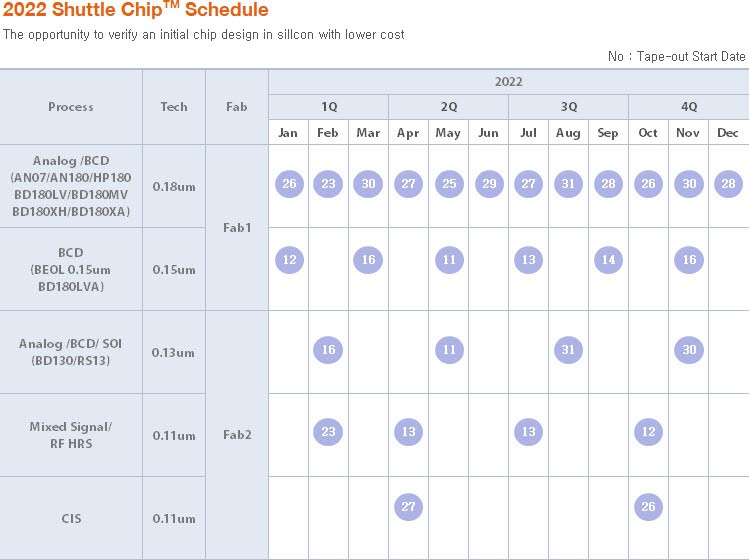

DB HiTek will additionally provide MPW service to semiconductor fabless this year. They decided to expand the request for BCD (Bipolar-CMOS-DMOS) process, which has soared in demand. DB HiTek plans to provide a total of 28 MPW services this year, which is about 20% more than their regular schedule. In terms of the number of simple MPWs, about 5 more times are added. Compared to last year's total serving, it is expected to be similar or slightly increase.

The reason DB HiTek receives additional MPW requests is to meet the growing demands of fabless customers. Since last year, fabless MPW demand has surged. MPW is a process that manufactures several semiconductor products on a single wafer and is essential for new product development. An official from DB HiTek said, “Last year, we received additional irregular MPW schedules due to the heavy demand for additional MPW from fabless. This year, as there is a lot of demand for fabless, we plan to secure 20% additional lines and receive service requests.”

As a result of DB HiTek's analysis of fabless customer trends, it was found that there will be a large demand for MPW to utilize the 130-180 nanometer BCD process. Accordingly, additional lines to be allocated are likely to be concentrated on the BCD process. BCD is used in the manufacture of various semiconductors such as display driver IC (DDI) as well as automotive semiconductors, which have recently suffered from a lack of semiconductor supply. As a result of the MPW demand survey of 72 domestic fabless companies for 2022 by the Innovation Center for System IC, it was found that the number of fabless where wants to use DB HiTek increased 2.5 times compared to the previous year.

The industry is considering that DB HiTek 's decision is exceptional. This is because MPW lines, which are not highly profitable, are additionally allocated while the foundry mass production lines are already in full operation due to a lack of semiconductor supply. It is evaluated that it is not an easy decision as other foundry companies are reducing or partially adjusting their MPW lines this year. DB HiTek's mass production line was closed by the second quarter. The line is expected to be fully operational in second half.

It is known that the allocation of the MPW line was a result of reflecting the will of DB HiTek Vice Chairman, Chang-sik Choi. Recently, as the foundry MPW has been attracting attention as a win-win strategy with fabless, it became important that how much MPW they can provide is becoming a measure of win-win cooperation. This is because the development of fabless prototypes is at ease. It is reported that Vice Chairman Choi directly emphasized the strengthening of MPW to support fabless. An official from DB HiTek said, “DB HiTek has been steadily expanding MPW for fabless growth for the past 20 years We plan to help develop fabless prototypes without downsizing MPW business again this year.”

By Staff Reporter Dong-jun Kwon (djkwon@etnews.com)