KLA 54 cases · ASM 24 cases · ASML 20 cases

Only 2 cases from SEMES and 1 case from PSK in Korea

Directly related to productivity such as wafer transfer and defect analysis

Domestic equipment develo

It was found that foreign companies have virtually monopolized the artificial intelligence (AI) patents used in domestic semiconductor equipment. Some domestic companies have also started to secure AI patents, but they are far from achieving it. There is a high concern that Korea's semiconductor equipment competitiveness will lag behind as it falls behind in AI technology, which is the key to improving semiconductor process productivity.

The Next Generation Intelligence Semiconductor foundation, in collaboration with the Korean Society for Semiconductor and Display Technology, conducted a study on the competitiveness of AI patents for the top 10 foreign semiconductor equipment companies and 10 domestic semiconductor equipment companies. The result confirmed that foreign companies accounted for 98% of domestic semiconductor equipment-related AI patents. The largest number was the US’ KLA with 54 cases. ASM and ASML followed with 24 and 20, respectively. Hitachi High-Tech filed for 12 and Applied Materials for 11. There were only three cases in total for domestic equipment companies; two from SEMES and one from PSK.

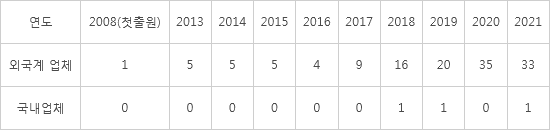

Foreign companies have applied for AI-related patents in Korea since 2008. Although most global companies customarily apply for patents in multiple countries, they have implemented a strategy to secure exclusive rights to technology early. Hyung-joon Kim, head of the Next Generation Intelligence Semiconductor Foundation, evaluated and said, “Considering that most patents are released after 18 months, foreign companies are in a hurry to secure rights through early disclosure and preferential examination.” In particular, since 2017, when the semiconductor supercycle began in earnest, the number of patent applications by foreign companies surged. Domestic companies did not apply for a patent until 2018.

The utilization of AI technology in semiconductor equipment is directly related to productivity. It is applied in wafer transfer, process recipe optimization, and defect pattern analysis. This reduces the process time and the cost of semiconductor production, while increasing product yield. The industry evaluates that the applying AI technology to semiconductor equipment can increase productivity up to 10 times.

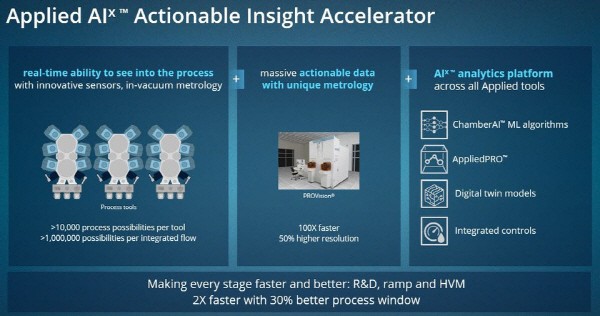

If patent rights are not secured in a timely manner, the competitiveness of semiconductor equipment will decrease. This is because foreign equipment manufacturers have already introduced AI-applied semiconductor equipment and are supporting semiconductor manufacturers to improve their productivity. Applied is optimizing the process sequence with its AI platform. Lam Research is marketing that its biggest strength is the ability to reduce the number of experimental designs and costs by 20% through AI technology. KLA and TEL also applied AI to their measurement and test equipment.

AI patent competitiveness also creates barriers to entry into the next-generation semiconductor equipment market. If a foreign company secures a patent first, due to the similarity of the semiconductor manufacturing process, then it can halt the development of domestic equipment.

Director Kim emphasized and said, “The introduction and development of AI patents for domestic semiconductor equipment are unexpectedly lagging behind. It is necessary to pursue AI patent applications in areas that are relatively easy to introduce, such as diagnosis and testing.”

◇ AI patent application trend related to semiconductor equipment by year

(Unit: Pieces)

Multiple applications for AI-related patents by domestic and foreign equipment companies

<Table provided by Next Generation Intelligence Semiconductor Foundation>

By Staff Reporter Dong-jun Kwon (djkwon@etnews.com)