A South Korean display materials manufacturer called Jeong Kwan has begun working on development of solid electrolyte that is drawing attention as a key material for all-solid-state batteries (ASSB). Not only is the company working on sulfide-based electrolyte, but it is also working on oxide-based solid electrolyte at the same time. It has built a production line for sulfide-based electrolyte that is known to have zero risk of explosion and excellent ionic conductivity and is currently working on pilot production with a South Korean battery manufacturer. Sulfide-based electrolyte in particular is drawing most attention from the battery industry due to its excellent performance compared to other solid electrolytes.

According to the industry on Tuesday, Jeong Kwan (CEO Kim Tae-heung) is currently working on development and mass-production of solid electrolytes which will be used for ASSBs. The company has built a pilot line in Yangsan and it has been carrying out pilot production of solid electrolytes.

The company is currently the only South Korean company to have built a pilot line for solid electrolytes. Although the exact annual production capacity of solid electrolytes is not known, the industry believes that the company’s pilot line is able to make tons of solid electrolytes annually. The company is currently making solid electrolyte utilizing sulfide and is working with a South Korean battery manufacturer to test its production.

The company actually specializes in materials and parts used for displays. However, it has been expanding its business towards battery materials.

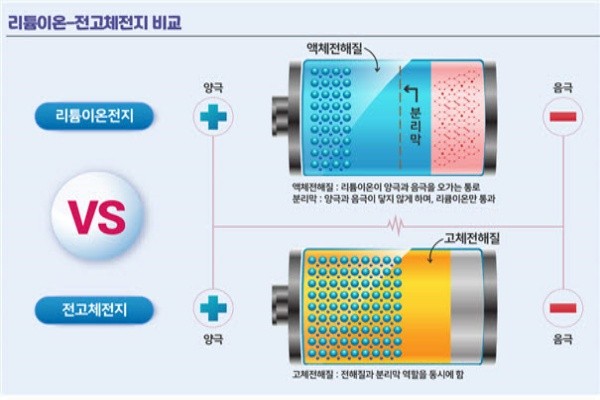

ASSB basically uses solid electrolyte instead of liquid electrolyte and does not have any risk of explosion. However, solid electrolyte typically has lower ionic conductivity compared to liquid electrolyte. As a result, the industry has been utilizing sulfide and oxide in order to develop the best ASSB when it comes to performance and price.

Sulfide-based solid electrolyte that Jeong Kwan has been working on is known for its excellent ionic conductivity. This is the reason why battery manufacturers such as LG Energy Solution, Samsung SDI, and Toyota have been focusing on development of sulfide-based ASSB.

Jeong Kwan has actually been working on oxide-based solid electrolyte since 2012 because the production process of oxide-based electrolyte is very similar to the production process of glass frit that is one of display materials that the company specializes in.

Based on its knowhow in production of oxide-based electrolyte, the company also began working on commercialization of sulfide-based electrolyte. The company is determined to push forward commercialization of sulfide-based ASSB by developing technologies necessary for mass-production of sulfide-based solid electrolyte and verifying yield of its production.

The exact time on when the company will begin to mass-produce sulfide-based electrolytes is not known. However, because it has already built a production line and has been working on solid electrolyte for a while, it is expected that its solid electrolytes will be used for electric vehicle batteries around 2025 when sulfide-based ASSB is expected to be commercialized.

A representative from Jeong Kwan said that it will still take some time for the company to actually start mass-production of solid electrolytes and that it will continue to do its best to push forward commercialization of sulfide-based solid electrolyte as it has built knowhow in solid electrolyte for a long time.

Staff Reporter Kim, Jiwoong | jw0316@etnews.com