The South Korean Government is going to be the first government to develop world’s first “soft error” test equipment that currently does not exist within the global semiconductor industry. Soft error indicates a temporary error that occurs due to neutrons in the air. As more autonomous vehicles, which require a high level of safety for passengers, mounted with semiconductors, it has become important to test and rectify soft errors in advance.

In order to develop this equipment, major semiconductor companies, materials, components, and equipment makers, and government institutions will work together. When this equipment is commercialized, the semiconductor industry will able to greatly reduce time and cost compared to relying on foreign testing systems. Also, it is expected that domestic semiconductor chip’s reliability will be improved greatly and that the industry will be able to get a head start in next-generation equipment markets that are based on totally new concepts.

According to the industry, South Korea’s major semiconductor companies and materials, components, and equipment makers will work together on a national project that involves development of soft error test equipment.

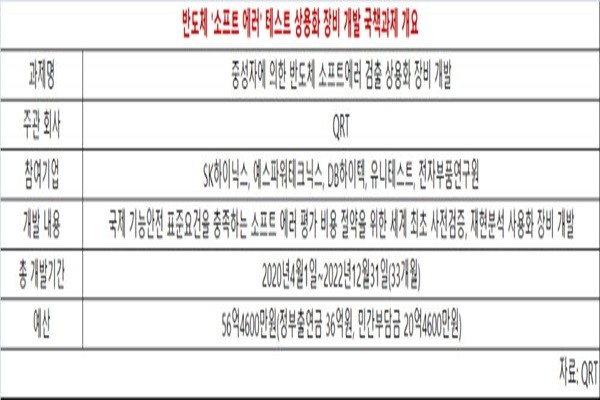

This project will be supervised by QRT that specializes in testing of semiconductor component’ reliability and analysis of defective products. Under QRT’s supervision, major semiconductor companies, materials, components, and equipment makers, and national research institutions will participate in the project.

SK Hynix will participate as a buyer of such equipment while DB HiTek, Yes Powertechnix that makes next-generation power semiconductor called Silicon Carbide (SiC), a test equipment maker called UniTest, and Korea Electronics Technology Institute (KEIT) put their heads together. National budget worth $2.96 million (3.6 billion KRW) and private contributions worth $1.68 million (2.046 billion KRW) will be invested in the project.

“Commercialization of soft error test equipment” is very meaningful as it will be the very first attempt within the global industry. Because integrated circuit’s thickness has fall into nanometer range, the global semiconductor industry has to be sensitive about penetration by neutrons. Also, because there is an increase in number of semiconductors that go into cars such as autonomous vehicle, a temporary error is directly led to passenger’s life. As a result, soft error has been emphasized as an important issue within the global semiconductor industry. ISO 26262, an international standard for functional safety of electrical and electronic systems in automobiles, also emphasizes the importance of soft error certification.

Measurement of soft error usually takes at the end of chip development. However, methods of measuring a soft error are limited significantly. South Korean chip makers cannot perform a neutron test in South Korea as there is no neutron accelerator in South Korea.

As a result, they have to rely on foreign countries for measurement system and certification. IROC Technologies based in France is a primary example. South Korean chip makers spend up to $400,000 annually for testing and certification.

When soft error test equipment is developed, a testing system can be then commercialized by South Korean companies. Test equipment will be made so that its size is similar to that of a desktop in order to raise convenience level and speed.

It will be also designed according to the current state of South Korea that does not have a neutron accelerator. It will be made so that early verification can take place even with a proton accelerator.

“Our goal is to develop an equipment that can predict impact level of neutrons through experiments using protons.” said Gi Joong-sik who is a member of QRT’s research committee. “Unlike neutron, travel path of a proton can be controlled which allows us to carefully analyze the location of a soft error within a chip.” He also added that this equipment will help the R&D sector entirely while current testing systems only focus on certification.

Another advantage of this equipment is its ability to test “alpha particle”, which is another cause of a soft error, on a desk.

It is expected that this equipment will be a much-needed rain for the semiconductor industry that lacks testing infrastructures. It is expected that relevant companies will share areas that are lacking and greatly raise the level of completion of this equipment.

Some also predict that development of this equipment will be a catalyst to bringing in a neutron accelerator to South Korea.

“Although a neutron accelerator’s price is astronomical, we need to invest in testing infrastructures as we are the top country in memory semiconductor.” said a representative for the industry. “We expect that our industry will have both proton accelerator and neutron accelerator in the future so that the industry can freely perform necessary tests.”

Staff Reporter Kang, Hyeryung | kang@etnews.com