Hydrogen fluoride is a chemical that is used heavily during ‘cleaning’ process of semiconductor process. A semiconductor chip is made by having thin layers stacked on top of each other on a silicon wafer. Hydrogen fluoride removes any substance (oxide film) that is created naturally when layers are placed on top of each other. While removing unnecessary substance, hydrogen fluoride makes electrical connection. Liquid form of hydrogen fluoride is usually used and more than 70% of liquid hydrogen fluoride markets in the world are owned by Japanese businesses such as Morita and Stellachemifa. Ever since Japanese Government decided to regulate exportation of hydrogen fluoride, representatives from Samsung Electronics and SK Hynix are busy looking for alternatives around the world. Although there are South Korean businesses that possess technologies for refinement, level of their technologies are currently not at the level of Japanese technologies.

A semiconductor chip is made after going through 500 to 600 processes for several months. Each layer on top of a silicon wafer transfers electrical signals with each other to process and send information.

Semiconductor process is repetition of placing a thin layer on top of a wafer, projecting circuit, and placing another layer on top of the bottom layer.

However, oxide film naturally occurs whenever a new layer is placed on top of a finished layer. Oxide film that is created as a layer naturally rubs against oxygen of air impedes connection between layers and causes high resistance.

Hydrogen fluoride is used to remove oxide film. Just as a person sands a machine whenever it becomes rusty as it comes in contact with air, hydrogen fluoride removes oxide film and maximizes connection between layers. There will be more faulty products at the end when hydrogen fluoride is not used for cleaning process leading to higher dissatisfaction from customers.

Hydrogen fluoride that is usually used during semiconductor manufacturing process is in liquid form. Liquid hydrogen fluoride is poured into a huge bowl and is then used to clean any oxide film on a wafer. Hydrogen fluoride in gaseous form has also been used for many years. It is mixed with various substances and removes any oxide film and residue.

Because hydrogen fluoride actually shaves off stain, cleaning process can be seen more as etching process. This is the reason why Japanese Government mentioned ‘etching gas’ in addition to hydrogen fluoride when it announced its regulation.

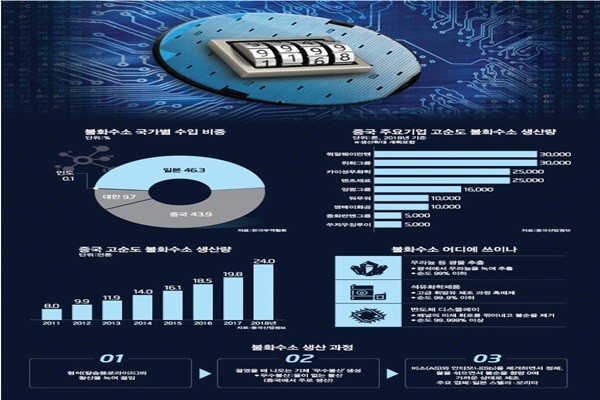

Hydrogen fluoride goes through many processes before it actually touches a wafer inside of plants of Samsung Electronics and SK Hynix. Entire process begins when hydrogen fluoride involves the reaction of sulfuric acid on fluorspar. Anhydrous hydrogen fluoride in gaseous state is produced when fluorspar is boiled and it is mostly produced from China. This is why some say that China is just as important as Japan when it comes to supply of raw materials.

Anhydrous hydrogen fluoride goes through refinement to become hydrogen fluoride that is used by semiconductor industry. Due to a characteristic of anhydrous hydrogen fluoride that stays in gaseous state at room temperature, process of converting anhydrous hydrogen fluoride in gaseous state to liquid hydrogen fluoride is carried out.

In addition, hydrogen fluoride with ultra-high purity is made by removing impurities such as arsenic and antimony. Stella and Murita specialize this process. These businesses manufacture 12N (99.999999999%) hydrogen fluoride. It is heard that Japanese businesses also hold the lead of etching gas market.

South Korean businesses that receive hydrogen fluoride with ultra-high purity from Japanese businesses carry out refinement process while removing impurities that may appear during transfer process. They then dilute hydrogen fluoride with DI water because concentrated hydrogen fluoride can remove necessary substances as well.

Price of hydrogen fluoride with ultra-high purity is very expensive as it is an important material preventing faulty semiconductors. “Price goes up by 30% even when purity goes from 99.9% to 99.99%.” said a representative for the industry.

Because Japanese businesses own core technologies for refinement process, Japanese Government targeted South Korean semiconductor industry’s ‘vital area’ with its regulation. Fact that there are not suitable replacements in South Korea is another issue. Even if South Korean Government comes up with alternatives by working with South Korean businesses, they have to adjust entire semiconductor processes from the beginning.

“Although many South Korean businesses are being mentioned, it will take long time to replace quality of Japanese products.” said an expert from the industry. “Speed of localizing hydrogen fluoride has been slow due to insignificant collaboration between major corporations and small and medium businesses and conflicts between civic groups and businesses as hydrogen fluoride is deadly poisonous chemical.”

It is heard that Samsung Electronics and SK Hynix dispatched employees from their purchasing departments around the world to look for alternatives.

Samsung Electronics is looking into receiving hydrogen fluoride from a global chemical business as part of its plan to diversify sources of hydrogen fluoride suppliers. It is heard that it is also preparing tests to localize hydrogen fluoride.

“SK Hynix is also looking into localizing hydrogen fluoride by going through tests with South Korean businesses and increasing supplies.” said a representative for the industry.

Staff Reporter Kang, Hyeryung | kang@etnews.com