South Korean small and medium company has developed QDEF (Quantum Dot Enhancement Film) technology that is able to make QD (Quantum Dot) TV less expensive and thinner. This technology is resistant against heat, water, and air contact and does not require a barrier film that is attached to QD TV in order to protect QD material. This company also mass-produced QD lighting with better color rendering by attaching QDEF to current LED lighting since it is resistant against heat.

GL Vision developed stable QD material that is nearly not affected by heat, water, and oxygen and applied it to QD lighting. It is currently developing QDEF that has higher color representation power by attaching QD material to current LCDs.

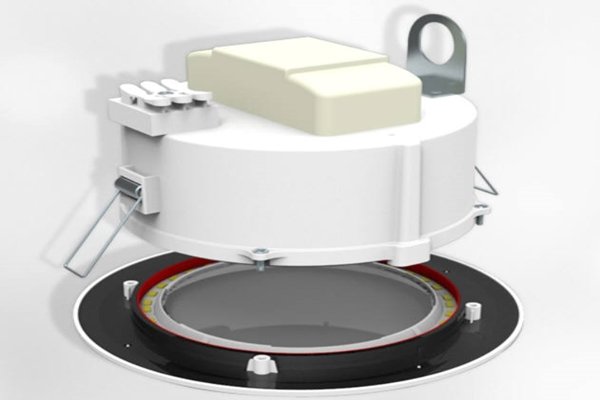

GL Vision developed QD powder by applying its own technologies to QD material that is in a form of solution. It also manufactured QD film and QD pellet for lighting by using this QD powder. QD lighting can be made by either attaching QD film to LED lighting or putting QD pellet into LED modules.

“While generally color rendering of LED lighting is between 79 and 80Ra, LED lighting with QD pellet increases color rendering up to 95Ra.” said Technical Director Yoo Wang-geon of GL Vision. “Due to possibility of emission of QD pellet from its characteristic of being resistant against heat, it can be used for lighting and it can prevent glare and reduces degree of fatigue of eyes.”

“Because QD lighting has higher color rendering and color representation power than regular LED lighting, it is good for indoor down-light or industrial lighting that needs to accurately understand color.” said Technical Director Yoo. “We are currently discussing with South Korean and foreign companies regarding supply of QD lighting.”

Because its QD material is resistant against heat, air, and water, QDEF can be made without using a barrier film. GL Vision is currently developing QDEF for heat-resisting displays that do not require barrier films.

Barrier film protects QD from oxygen and water. It protects it from oxygen and water contact by breaking up quantum dot into resin and making it into a sheet and covering it with two barrier films.

However barrier film has high degree of technical difficulty and is expensive as it is responsible for about 20 to 30% of QDEF price. Barrier film is about $30.

If a barrier film is not used in manufacturing QDEF, thickness of it can be reduced by a lot. GL Vision explained that if thickness of QDEF is 300 micrometers, thickness of QDEF that does not have a barrier film can be 100 micrometers or lower.

Thinner TV can be made if thickness of a part is reduced. Because price of the part can also be reduced, manufacturing cost of QD TV can also be reduced which results in lower unit cost.

“We expect to increase added values in LED lighting industries through QD material with higher stability.” said a representative for GL Vision. “We are going to finish developing QDEF without a barrier film and inform our products with a goal of supplying it to South Korean and foreign markets.”

Staff Reporter Bae, Okjin | withok@etnews.com