South Korean research team has developed a system (Selective Catalytic Reduction (SCR) system) that can convert nitrogen oxide of exhaust gas that is emitted by large vessels into nitrogen and vapor without any contaminants. This system satisfies tightened regulations on emission of nitrogen oxide and is expected to be used widely for vessels that will be built in the future.

Korea Institute of Machinery & Materials (KIMM, Director Park Chun-hong) announced on the 30th that a research team led by Professor Jung Kyung-yeol of Energy Plant Safety Laboratory has developed a SCR system that responds to two-cycle diesel engines for vessels and succeeded in satisfying tightened regulations (tier III) on emission of nitrogen oxide.

IMO (International Maritime Organization) is requiring vessels that are built after 2016 to reduce emission of nitrogen oxide 78% more than the level that tier II requires. Although vessels were able to satisfy regulations with improved engine combustion technology, there is a need for technologies that can further reduce amount of nitrogen oxide due to tightened regulations.

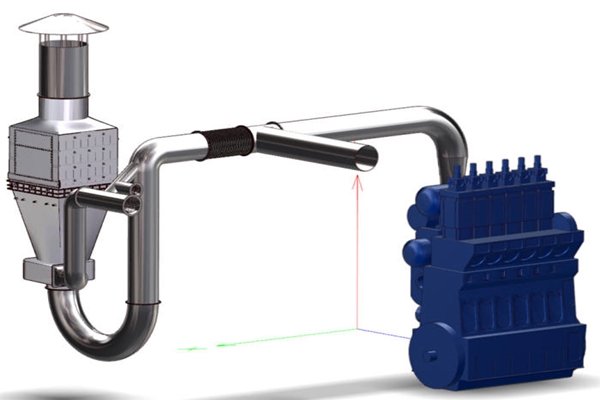

SCR system developed by the research team reduces nitrogen oxide into nitrogen and water through ammonia and exhaust gas and is composed to catalytic reactor, reducing agent supplying system, exhaust gas pipeline, smoke reducing device, and duct burner. Its characteristic is that it can also be used for engines with low temperature of exhaust gas between 200C and 300C.

Temperature of exhaust gas is the yardstick that shows efficiency of an engine. Most of high-efficient engines have low temperature exhaust gas. However because reduction and separation of nitrogen oxide does not occur if thermal efficiency is low, there was a need for a separate catalyst for low temperature.

Research team was able to solve this problem by designing an optimum equipment. It increased reactivity by spraying ammonia solution, which is used for reduction, under a size of 20 micrometers. It also increased efficiency by automatically controlling amount of ammonia that is supplied depending on changes in output of an engine.

Research team also minimized pressure that is exerted on an engine. Usually when an additional system is installed to an engine, there is pressure on an engine due to increase in back pressure (pressure of gas that comes from internal combustion engine). Research team was able to lower back pressure by designing an optimum system.

Research team explained that it was able to obtain results from emission of nitrogen oxide that satisfy international regulations after going through tests on the land and the sea. While tests on the land were carried out through a vessel with 10,000 horsepower, tests on the sea were carried out through a training ship called Hanbando-ho with 3,800 horsepower. It is planning to develop SCR systems that correspond to variety of vessels and sizes of engines and it already secured a technology that can design customized SCR systems.

“After 6 years of research, we were able to develop after treatment system for exhaust gas that comes from a diesel engine of a vessel.” said Professor Jung, Kyung-yeol. “Not only this system will allow us to grab upper hands in South Korean markets but it also lays out ways for us to expand global market shares.”

Staff Reporter Kim, Youngjoon | kyj85@etnews.com