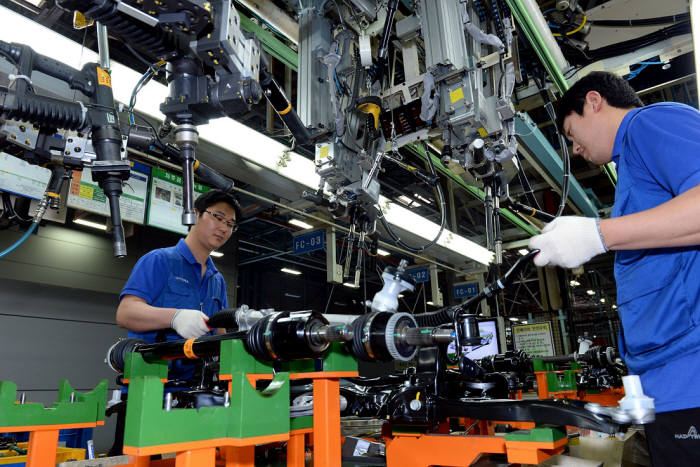

Hyundai Mobis, the Hyundai Motor Group affiliate manufacturing core parts, is standardizing its global production processes this year in a bid to acquire world-best quality competitiveness. After Hyundai & Kia, auto makers belonging to the group, produced and sold 8 million cars around the world, it has emerged as a core task to improve the quality of core parts and modules while concentrating on basic competitiveness, rather than rapid quantitative expansion.

Hyundai Mobis (CEO Chung Myung-chul) announced on February 11 that it would concentrate on standardizing the production processes of the 15 production subsidiaries in 8 countries and improving quality competitiveness.

Standardization of production processes is a measure to minimize defects in all processes from the receiving of key parts to logistics in the plant, production, inspection and shipping. In particular, it is a core strategy for accomplishing the catch phrase ‘C&C (Change and Challenge) 350’ that the company newly introduced earlier this year to enhance employees’ awareness of quality. C&C 350 means the ‘accomplishment of CS10000 5.0 in 3 years.’ CS10000 is a quality index meaning the number of defects per 10,000 products. It is equivalent to the defect rate of 0.05%.

“C&C 350 expresses the will to become the world’s best automotive parts maker through change and challenge becoming the 6th largest company in the global automotive parts industry,” said a Hyundai Mobis insider. “In 2015 the focus of all our management activities, including reinforcement of cost competitiveness and development of new original technologies, will be placed on improvement of basic quality.”

This strategy of Hyundai Mobis is in synch with the Hyundai Motor Group’s strategy of reinforcing the competitiveness of its products and enhancing the brand value by improving quality in the face of such business conditions as the ever increasing competition in the industry, the sluggish emerging markets and strong Korean Won. In the belief that focus must be placed on the basics to proactively respond to the uncertain global business environment, the company is stressing the importance of substantive management. In particular, it is necessary to improve the fundamental quality competitiveness in order to effectively support Hyundai & Kia and increase supplies to other overseas auto makers.

A Hyundai Mobis insider said, “With the competition in the global automotive industry intensifying in recent years, the management reached a consensus that further reinforcement of the basic competitiveness, particularly, quality will be the biggest innovation.”